- #Descargar cnc simulator full how to#

- #Descargar cnc simulator full serial#

- #Descargar cnc simulator full manual#

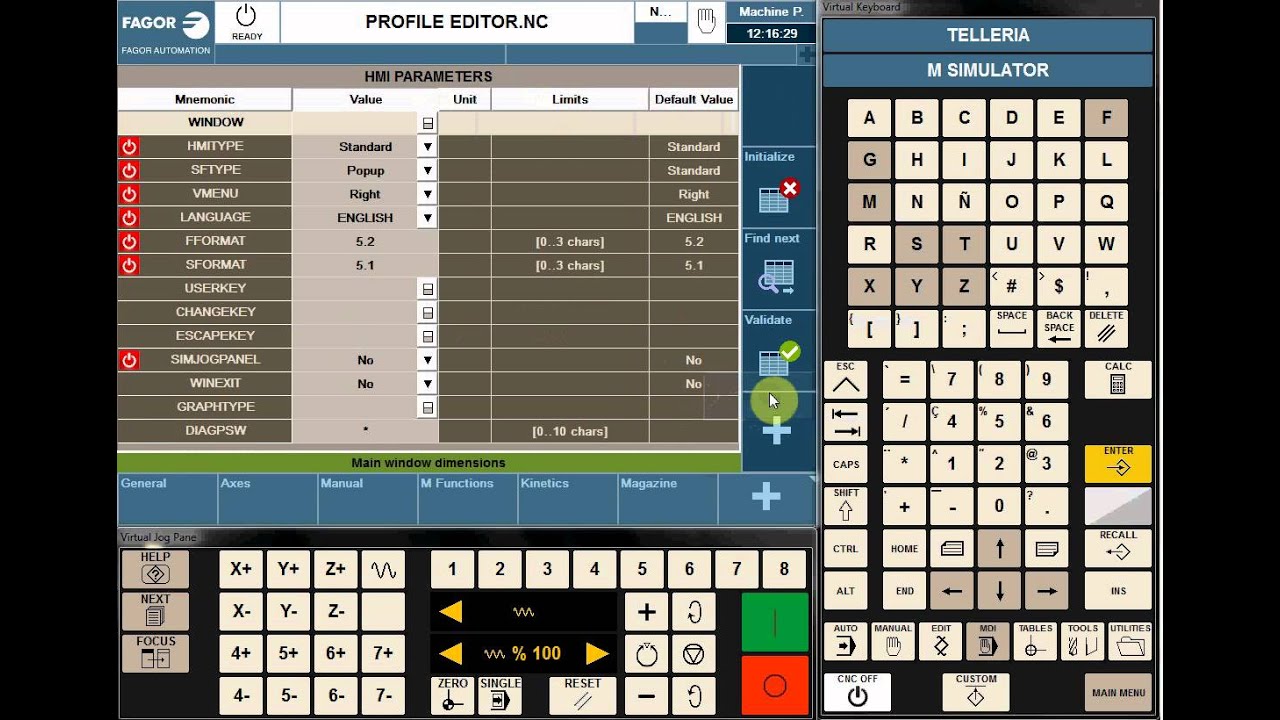

You can import the machine data of your real machine tools into the full version. This innovative part programming operation environment focuses the student on machine operations, rather than just Gcode, allowing a job to be completed in the shortest time possible.Licensing: SinuTrain and the machines of your workshopīy licensing the "SinuTrain for SINUMERIK Operate" basic version becomes a full version.

#Descargar cnc simulator full manual#

Process-orientated conversational programmingįor students advancing to a smaller job shop or tool room, user-friendly MANUAL GUIDE i conversational programming simplifies and enhances their productivity. Features such as FANUC’s dual-screen display are standard features, so with additional PC software instructors can replicate the screen of the simulator on a PC, via the Ethernet connection for instructor-led classes on a projector. Students can perform operations and programming exercises away from the machine and then simply take the program to the machine.

#Descargar cnc simulator full serial#

Optional I/O link i and RS232 serial interface.USB, Flash ATA and Ethernet connectivity.Workpiece coordinates G52 – G59 plus 48 additional on mill.512KB part-program storage, with 400 registered programs.Manual Guide i installed for conversational program creation and 3D simulation.3-axis milling / 2-axis turning system plus one spindle.Switchable mill and lathe (turning) system in one simulator.Uploading and downloading (read and punch) functions are facilitated by means of the standard Flash ATA interface and USB interface, and DNC functions are supported by Ethernet and Flash ATA card. FANUC’s MGi conversational interface allows user to graphically generate programs that can be simulated in 3D, prior to being converted back to conventional NC programs to be used on machine tools using FANUC controls.

#Descargar cnc simulator full how to#

Simple configurations make it easy to learn how to operate and edit data on a modern FANUC control. Based on the FANUC 0iF platform, the simulator will allow you at power on to switch between milling and turning configurations to teach programming, navigation, and operation on the world’s most popular CNC control. The FANUC CNC simulator is a perfect addition to the classroom and an essential component to gain maximum exposure to FANUC CNC controls when actual machine time is limited. Manufacturers Amatrol DAC Worldwide Stratasys FANUC Lincoln Electric APT Manufacturing Solutions Artec Bayport BOFA Americas BÖHLER Edelstahl Cyber Science Denford Desktop Metal EduSmart Levil Technology LJ Create Lucas-Nuelle Marcraft MINDS-i Robotics MSSC OilTec OnRobot Renishaw sciTEX SimLog SimSpray SynDaver Labs TacMed Solutions Universal Laser Systems Wartsila.Colleges & Universities 3D Printers 3D Scanners Anatomy Models Laser Cutting/Engraving Fume Extraction Mechatronics Chemical Engineering.

0 kommentar(er)

0 kommentar(er)